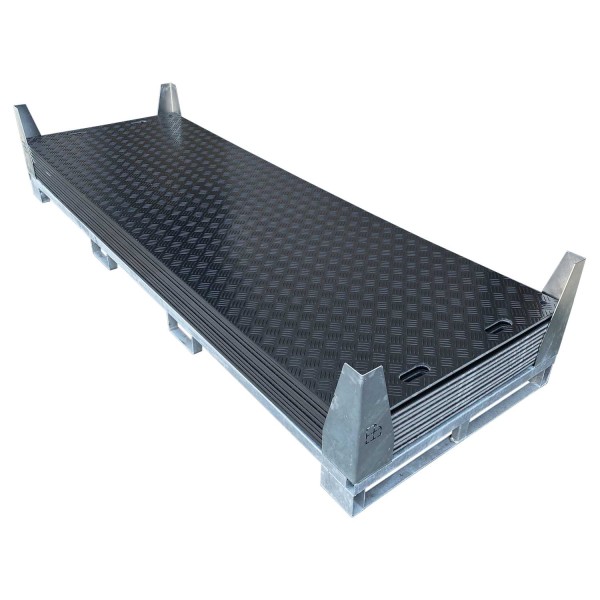

e:tek PRO · Road Plates Set

10 Road Plates a 3,00m² = 30,00m² / 30,00 lfm incl. steel pallet with corner angle set. Connectors for Road Plates available as accessories.

- 3000 x 1000 x 20 mm | 55 kg

- Load capacity up to ¹45t | ²18t | ³5t **

- Profiled on one side

- 4 connection holes

- 4 handle holes

- LDPE plastic

- Order number: ET-PRO-SET10-10-ST400

Features & Highlights

Awesome price-performance ratio

install by hand

with high slip resistance

in building & construction

many construction vehicles

The e:tek PRO Road Plates are available in four different drive-over plate set sizes, as a set of 10, set of 20, set of 30 incl. steel pallet with corner angle set or folding angle set. The precisely fitting and loading space optimized drive plate box (steel pallet + 4 angles), is thereby hardly larger than the Road Plate itself. The e:tek PRO plastic Road Plates or drive-over plates are 3000×1000×20 mm, cover an area of 3.00 m² and are about 55 kg light. On the top of the driving plate there is a approx. 2 mm thick anti-slip profile structure, the underside is without profile.

Which road plate set sizes are available and what do they contain?

There are usually 3 set sizes to choose from. Usually there are sets of 10, sets of 20 or sets of 30, where the number indicates how many driving plates the set contains. In addition to the drive plates, the set always includes a drive plate box consisting of a SmartStore steel pallet and 4 SmartStore corner brackets. You will find a detailed list or set parts list for the respective set in the "Technical data" tab under "Set contents".

- sets of 10 driving plates

- 20er driving plates sets

- sets of 30 driving plates

Why does the moving platen set not include any connectors or connecting clips?

On the one hand, the choice of the right connector depends on the surface on which the panels are to be laid, and on the other hand, the number of connectors required depends on how the panels are to be laid out. Plastic connectors must always be used when a firm, hard, sensitive floor covering such as paving, concrete, porcelain stoneware, hall floors or coated industrial floors is to be protected from damage. Round steel connectors, in turn, may only be used on soft, unpaved ground such as, lawn, meadow, gravel, farmland, etc. To answer the question of how many connectors are needed per driving plate, we recommend the following quantities as a rough guide based on experience:

Recommended number of connectors, per plate:

- Lane, 1-lane = 2x "2-fold connectors"

- Lane, 2-lane = 2x "2-fold connector" + 1x "4-fold connector

- Platform / Flat = 1x "4-way connector" + 1x "4-way connector"

Do the e:tek PRO drive-over plates have an anti-slip profile?

Yes, the 20 mm thick e:tek PRO drive-over plates made of LDPE plastic have a structure profiling on one side. The profile thickness on the upper side is approx. 2 mm and, thanks to the checker plate structure, ensures improved safety and slip resistance for man and machine, on any terrain, in any season, in any weather.

- One-sided profiling

- Chequer plate structure

- Easy to clean

Do the e:tek PRO driving plates have grip holes and also holes for connecting?

The plastic driving plate has connecting holes at each corner for easy coupling of the plates by means of driving plate connectors made of plastic (for firm floors) or connectors made of steel (for soft floors). There are 2 finger holes in the short side of the plate. Thanks to the total of 4 grip holes and the low dead weight, plastic plate is very easy to carry and just as easy to lay. The load capacity** is up to approx. 45t on paved & dry ground, up to approx. 18t on unpaved & dry ground and up to 5t on unpaved & wet ground.

- 4 grip holes (2 per short side)

- 4 corner holes for connecting

In which applications have the e:tek PRO drive-over plates proven themselves?

The extremely robust and solid plastic driving plate reliably protects the ground, no matter if it is meadow, pavement or other soils from loads. Our driving plates, soil protection plates and heavy-duty plates are often used as temporary access solutions, drive-over plates, load distribution plates, mobile driveways, makeshift roads or as access routes for excavators, trucks and construction machinery in construction site equipment and construction logistics. Drive-over slabs protect the subsoil, serve to distribute the load, prevent vehicles, machines and pedestrians from sinking in, and thus effectively reduce costs for costly ground reworking.

- Soil Protection & Pavement Protection

- Turf protection & pavement protection

- Driveways & construction roads

- Site equipment & construction logistics

- Storage areas & assembly areas

- Landscaping & Earthworks

- Events & functions

Why are plastic panels better than wooden panels?

The big advantage of plastic panels compared to wooden panels is that plastic panels do not rot, are heat- and frost-resistant, break-proof and extremely flexible and therefore reusable. Due to the profiling and connection options, the e:tek driving panels allow for improved safety and mobility. The particularly easy-to-handle plastic panels can be installed and removed in no time at all.

- Durable and frequently reusable

- Will not splinter, rot or weather

- Weather resistant & UV stable

- Frost & temperature resistant

| Set type | Trackway mats Set |

| Plates per set (piece) | 10 |

| Area per set (m²) | 30,00 |

| Linear meter per set (rm) | 30 |

| Set content (parts list) | 1 x SmartStore steel pallet, 10 x e:tek PRO - Long trackway mats, 4 x SmartStore corner angle 400mm |

| Product category | Soil protection, Trackway mats |

| Product line | e:tek - Light trackway mats |

| Length, per piece (mm) | 3000 |

| Width, per piece (mm) | 1000 |

| Height, per piece (mm) | 20 |

| Area per piece (m²) | 3,00 m² |

| Weight per piece (kg) | 55,00 |

| Weight per m² (kg) | 18,33 |

| Profiling (both sides) | No |

| Profiling (by type) 1 | 0 mm Smooth, 2 mm structuring |

| Profile thickness approx. (Page 1 | Page 2) | 2 mm | 0 mm |

| Connection holes per plate | 4 |

| Types of joints / laying | Baustrasse, Road, Lanes (1-lane, 2-lane, 2-lane in H-principle, multi-lane arrangement), Platform (optimal for storage areas, assembly areas, parking areas, container spaces) |

| Load capacity¹ - substrate fixed & dry (≤t/piece)** | 45 |

| Load capacity² - substrate unpaved & dry (≤t/pc)** | 18 |

| Load capacity³ - substrate unpaved & wet (≤t/pc)** | 5 |

| **Notes on load capacity | All data on load-bearing capacity and protective effect depend, among other things, on factors such as temperature, soil class, soil properties, soil bearing capacity, contact areas, dynamics & direction of force application, an assessment of the subsoil by the user or a soil analysis by a surveyor or geotechnical expert on the bearing capacity of the soil is recommended before each use. |

| Carrying handles (quantity) | 4 |

| Carrying handles (type) | Finger holes |

| Material (1) | LDPE Plastic (Recycled) |

| Material thickness (mm) | 20 |

| Thermal expansion | 1.8 mm/(m-10°C) |

| Surface (texture) | Smooth |

| Moisture absorption (%) | 0,015 % |

| Temperature range min/max (°C) | -30 / +70 |

| Melting temperature, approx | 120 |

| UV stabilized | Yes |

| Chemically inactive | Yes |

| Industries | Construction & building materials trade, Horticulture & Landscaping, Golf Course Construction & Maintenance, Track construction & rail traffic, Network construction & line construction, Pipeline construction & well sinking, Sports facility construction & leisure facility construction, Road construction & traffic route construction, Pond Construction & Hydraulic Engineering, Transport & Logistics, Wind Turbines & Solar Farms, Civil defense & relief organizations |

| Transport dimensions, approx. (mm/kg) | 3020x1020x550 mm | 619 kg |

| Transport quantity per truck, max: | 16 sets (960 m²) |

| Stackable | Yes |